Description

- Approvals : AS1530.4 (2005) and AS1905.1 (2015)

- Box Quantity : 12

- Single Units : Yes

- Size : 750ml

Product Information

- Expanding Polyurethane Foam

- High Performance – up to 4 hours fire rating in linear gaps

- Approved for 2 hour fire doorsets

- Approved to AS1530.4:2005 and AS1905.1:2015

- Excellent adhesion

- 50 times expansion of original volume

- Manufactured to ISO EN9001

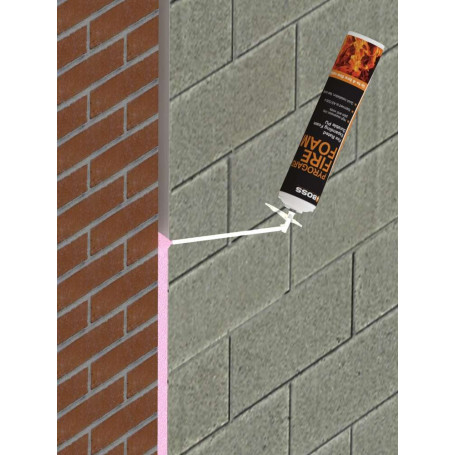

PYROGARD FIRE FOAM is a quick setting one – part polyurethane foam with excellent fire resistance properties.

PYROGARD FIRE FOAM expands on application to up to 50 times its original volume to fill any available voids and gaps , but without any excessive pressure on building substrates or wall structures . Approved for 2 hour fire doorsets, up to 2 hours in most joint configurations and 4 hours on concrete wall s, PYROGARD Fire Foam provides one of the simplest forms of fire rating irregular voids and apertures.

Once cured, the foam can be cut, sawn or plastered over within only one hour of application (based on an ideal working temp of 20°C).

| Expansion | 37 litres (750ml can) |

| Tack Free | Approx. 8 minutes |

| Cell Structure | Medium fine |

| Cuttable | 20mins to 1hr depending on bead dimensions |

| Full Stability | Approx. 12 hours (20mm bead) |

| Working Temps | 5°C – 25°C (Optimum 20°C) |

| Tensile Strength | 18N/cm² (DIN 53455) |

| Elongation at Tension | 30% (DIN 53455) |

| Shear Strength | 8N/cm² (DIN 53422) |

| Flexural Strength | 20N/cm² (DIN 53423) |

| Compressive Strength | 5N/cm² (DIN 53421) at 10% stress |

| Water Absorption | 0.3 Vol % (DIN 53428) |

| Thermal Conductivity | 0.04 W/Mk (DIN 52612) |

| Cured Temp Res | Long Term: – 40° to +100°C Short Term: – 40° to +130°C |

| Fire Test Data | Exova Warrington Report 326231A/B CSIRO Report FCO – 3001 |

Installation

- ALWAYS WEAR PROTECTIVE GLOVES.

- Shake can well before use (about 20 times).

- Carefully fix nozzle to the top of can . Do not over – tighten or force.

- ALWAYS USE CAN UPSIDE DOWN.

- Only partially fill cavities, as the foam will continue to expand after you release the nozzle to fill the remaining space . Any excess foam can be removed whilst still wet. Cured foam must be removed mechanically by cutting or sawing.

- Always remove nozzle from can/gun and clean immediately after use.