Description

- Approvals : AS1530.4, AS4072.1 and EN1366

- Box Quantity : 1

- Material : Graphite based Intumescent liner with steel shell

- Single Units : Yes

- Size (Thread/OD) : 65mm

Product Information

- Maximum Performance – up to 4hrs fire rated

- With approvals for Plasterboard, Masonry, Concrete, Speedpanel, & Hebel walls.

- Approvals for a wide range of pipes including uPVC & cPVC Sprinkler Pipes

- Sizes available from 32 mm – 250 mm diameter

- Only 40mm deep allows use in tight areas

- Tested to AS1530.4 , AS4072.1 and EN1366

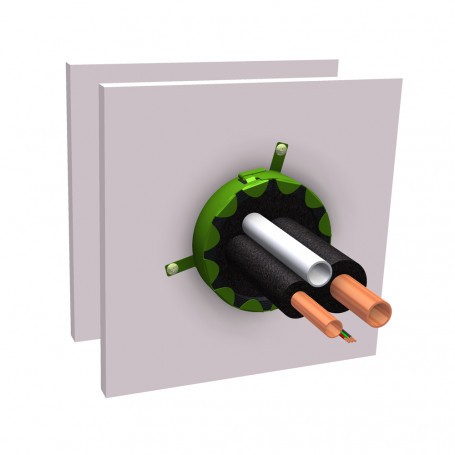

MaxiCollars™ set new standards in the use of retrofit pipe collars.

With a unique design and advanced intumescent technology, MaxiCollars™ provide one of the highest expansion rates available on pipe collars, providing maximum seal protection against fire and smoke.

Coupled with a unique profile of only 40mm depth, MaxiCollars™ are the best choice for tight fitting areas or closely installed pipes.

Suited to both walls and floors, MaxiCollars™ can be installed on the following structures:

- Batt mineral fibre boards (Figure 1)

- Speedpanel – with no need for additional plasterboard build up (Figure 2)

- Plasterboard and other drywalls (Figure 3 )

- Masonry and Block (Figure 4)

- Hebel /AAC

- Concrete (Figure 4)

Suited to a wide range of combustible pipes, MaxiCollars™ have been tested on uPVC, Polypropylene (PP) and Polyethylene (PE) in both capped and uncapped scenarios. MaxiCollars™ contain no fusible links or mechanical part s , giving a guarantee of activation in a fire situation.

Installation

MaxiCollars™ are designed to be bolted to the underneath of the concrete floor or surface mounted to walls. In wall situations one collar should be used on the outside of each face of the fire rated wall.

To fit the collar, open the collar by folding back the latching tab and sliding the collar ends apart. Wrap around the pipe and re – insert the fixing tab to close the collar. Fold back the tab to securely lock in place.

Mark the holes to be drilled at each tab onto the wall or floor and drill as required. Ensure only all – steel mechanical fixings are used – plastic or composite / alloy fasteners must not be used.

Gaps around pipe penetrations can be sealed with FireMastic – 300 fire rated sealant.